Education

Learn from the Museum

After all, what is electricity?

All electrical phenomena occur due to the existence of two types of charge, positive and negative. You have probably heard that same-sign electric charges repell and opposite-sign attract. Electrons are particles with negative electric charge and protons particles with positive charge. Protons and electrons, together with neutrons, which do not have any electric charge, make up the atoms of all that exists in nature.

We say an object has electrostatic charge when it shows an excess of electrons or protons and only electrons can be transferred from one body to another. Electrification can occur by contact, friction or induction. In the cases of contact and friction, electrons pass from one body to another: those that receive electrons are negatively electrified and those that lose electrons are positively electrified.

What about magnetism?

Magnetic forces also act at a distance, as do gravitational and electrical forces, which are also field forces. Magnetized bodies, such as magnets, set a surrounding magnetic field, which is responsible for the force they exert. The magnetic field lines flow in space surrounding the magnets and can also be mapped.

The magnets have poles called north and south. Similar to electric charges, equal poles repel and opposite poles attract each other. The similarities end here.

There is a fundamental difference between the electric and the magnetic nature of matter: the poles of a magnet cannot exist apart from each other, as occurs with electric charges. If we break a magnet in half, each half will have a north and a south pole; if we break it again, the two new pieces will still have a north and a south pole, and so on and so forth.

Are electricity and magnetism related?

Did you know that by the early 19th century, electrical phenomena were studied as if they were independent from magnetic phenomena? From 1820s, researches in these areas have led scientists from different countries to observe the relationship between these two fields of research. Gradually, they formulated the electromagnetic theory that unified the two areas of knowledge and facilitated the emergence of new technologies.

Largely responsible for this unification was James C. Maxwell who established in 1873 the equations that summarize the knowledge about electromagnetism and optics. The consolidation of this new look at nature paved the way for the scientific revolution that would arise with Albert Einstein´s theory of relativity in 1905.

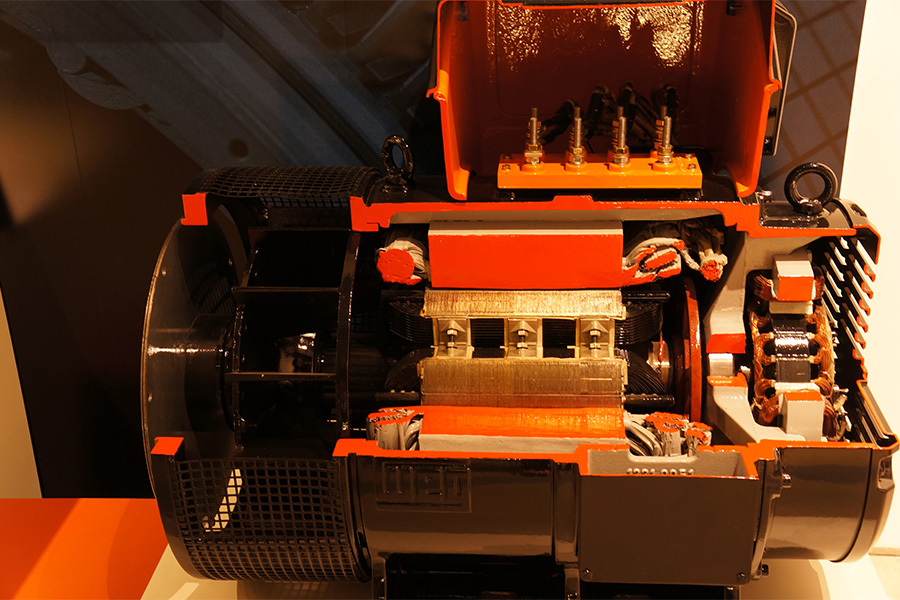

How does an electric motor work?

It works basically due to the interaction between electric and magnetic phenomena. In a simplified representation, the motor is composed coils (the rotor) properly arranged on top of fixed magnets (the stator). A magnetic field is generated around the coils when electric current flows through it, which interacts with the field of the magnets causing the coils to turn. The coils will not stop turning when a current reversal is applied at a determined frequency. We will have a motor when a shaft is coupled to these coils, which transfers this movement to the outside of the structure.

The electric motor transforms electrical energy into mechanical energy. The exhibit will show the operating principles of AC and DC motors.

Several researchers have contributed to the technological advancement of these machines, which contributed to the basic research in electromagnetism. In addition to Siemens and his DC motor and Tesla, who invented the two-phase induction motor, two other researchers stand out: Galileo Ferraris and Michael Dobrowolsky.

The AC motors quickly showed their advantages when compared to the DC motors: their construction was simpler, their operation quieter and safer, and they required less maintenance. This allowed Dobrowolsky to develop, in 1891, the first mass production of asynchronous motors.

“The AC motors […]were more silent, safer during operation and they required less maintenance.”

Manufacture and Assembly

Based on the design of a product, one must define all the steps and resources to manufacture and assemble the components so that it meets all specifications. Besides ensuring the quality, one must also consider the costs of the process so that the product is competitive in the market.

As simple as a part may be, it is rare for a single manufacturing process to be able to encompass geometric shapes, dimensions and desired final characteristics. To decide the manufacturing process involved, factors such as component shape, strength, accuracy and cost, among others, should be considered.

Foundry

Mechanical process used to obtain a molten metal product (aluminum, brass, bronze, iron or steel,etc.) which, once molten, is poured into sand (or steel) mold – negative of the product – where it remains until it solidifies.

It is the most economical process for making parts with complex shapes, containing grooves or internal ribs and which are difficult to be manufactured by any other process.

Each part cast in sand molds goes through shot blasting cleaning process for surface finishing removing burs and runners. Those with accurate bases or fits are subject to machining processes.

Machining

(Português) Usinagem é o grupo de diferentes processos mecânicos aos quais as peças são submetidas para obter as formas, dimensões e acabamentos finais desejados, onde ocorre remoção de material pela ação de ferramentas de corte.

Entre os processos mecânicos, as operações de usinagem permitem obter maior precisão dimensional, chegando ao nível de milésimos de milímetro (mícrons).Também produzem os melhores acabamentos superficiais.

As ferramentas de corte podem ser manuais, como as limas, serras e serrotes, ou montadas em máquinas operatrizes. Tanto as ferramentas como as máquinas têm características específicas para a obtenção de diferentes geometrias de superfícies.

A geometria da superfície que pode ser gerada e os movimentos de corte, de avanço e de profundidade são fundamentais para entender o funcionamento dos diversos tipos de máquinas operatrizes.

“[...] machining operations obtain higher dimensional accuracy, reaching the level of thousandths of a millimeter (microns).”

Plastic forming

This group includes mechanical processes in which permanent modifications of the geometric shape of parts are caused by the application of external forces below the ultimate material tensile strength, except in the process of sheet cutting, where the shear stress must exceed the shear strength. There is no material removal in these processes and they can be performed through cold or hot working.

The most common equipment to generate the required stresses are presses in which parts are formed with the aid of devices, fixtures, molds or dies. Bending operations, for instance, can be done manually without the need for any special equipment or device.

Besides stamping and drawing, the forging, rolling and extrusion processes are included in this group.

Stamping

Stamping is a cold forming or cold working process performed on thin strips of steel, copper, aluminum and other materials, where they are cut, folded and/or recessed. This effort is generated in a press over a tool specially built for a certain part or group of parts, called stamping.

The high cost of stamping process is only worth when a large amount of parts will be produced. The process is highly productive, generating smooth finish and uniformity among the parts.

Many parts present in our daily lives, such as plates of refrigerators and stoves, car bodies, computer and electronic appliance carcasses, lamps, among others, were obtained from the stamping process.

Wire drawing

It is the manufacturing process of wires and thin metal bars, such as steel, copper and aluminum.

It consists of stretching the material applying cold traction force through successive dies, each of them smaller than the previous section, resulting in the gradual reduction of material gauge and increasing its length. The resulting product has good surface finishing and low dimensional variation.

Coating

Starting at the Industrial Revolution, with the development of machinery and equipment, coating ceased to have just decorative purposes to also protect products from environmental aggressiveness, for instance, an oil platform motor should be weather and salt resistant.

In the production process, coatings are usually applied in two steps: primer, which occurs early in the manufacture of some components; and finishing paint, when appearance is also important.

The constant technological development in coat manufacturing is not limited to the improvement of chemical and mechanical properties. There is also a concern in obtaining safer and more eco-friendly coatings, apart from various other aspects. For example, cost reduction, which decreases the demand on surface preparation and allows application under aggressive environmental conditions.

Special procedures and assembly equipment

The equipment used in special procedures and assembly operations is specific to each product design. Companies need to design and manufacture their own equipment for these purposes, as there are no ready to use solutions on the market.

The Tooling Shop area is responsible for meeting such needs. It also produces stamping tools, foundry patterns and die casting molds, workholding devices for machining and for several other specific needs of the company.

Automation

The second half of the twentieth century was marked by an intense integration between scientific and technological research and industrial production. Semiconductors research led to the development of microelectronics, with the emergence of diodes, transistors, printed circuits and chips, which enabled the miniaturization of equipment.

With the diversification of hardware and software, the development of computer technology, along with microelectronics, completed the favorable scenario to technological developments of motors and generators. The result: unimaginable improvements in the performance of processes using such equipment.

Some of the electronic systems found in electrical machines are noteworthy: servomotors for sequences of repetitive operations; capacitors with electronic controls to correct the motor power factor; frequency inverters to vary speed; electronic drive systems that enables starting, stopping and protecting motors; regenerative inverters that recover part of the energy expended in lift braking and hybrid vehicles. With them, several handling operations that without electronics were previously performed manually or that were not even possible, are now performed through automation.

Thus, electronic systems provide improved safety, greater accuracy during operations and improved energy efficiency, ensuring increased productivity and increased compliance with sustainability goals, in addition to higher quality products and services.

“With the diversification of hardware and software, the development of computer technology, along with microelectronics, completed the favorable scenario to technological developments of motors and generators.”

Generators

The emergence of electromagnetism made the second industrial revolution possible. The first one, which began in the second half of the eighteenth century, had James Watt’s steam engine (1736-1819) as its main technological support.

The second [industrial revolution] starting at the end of the 19th century, witnessed the advent of several technological innovations, such as the internal combustion engine, the intensive use of oil and the growing use of electricity with the construction of power plants. The invention of more efficient electric motors also took part.

In 1879, European countries, the USA and Brazil started to use electricity. That same year, the light bulb was invented.

In 1883, Campos de Goytacazes, in the state of Rio de Janeiro, was the first city in South America to rely on public lighting services powered by a small thermal power plant.

In power plants, electricity can be obtained from various sources, such as the downward movement of water, the heat generated from the combustion of fuels and the energy released in nuclear reactions. Energy can be transformed from one type into another, but can neither be created nor destroyed.

Once generated, the electric power is transmitted through high-voltage cables to demand centers, where it becomes light in lamps, sound energy in radios and TV sets, mechanical energy for motor rotation, as well as heat in all pieces of equipment as they all heat up when used. In this process, some energy is lost in the form of heat, but if we could measure all losses and add them to the quantity that was actually used, we would get the same initial value generated at the plant. This is due to one of the most important regularities in nature, known as the principle of energy conservation.

Two nineteenth-century researchers stand out for their contributions to the development of electric generators: Werner von Siemens and Nikola Tesla.

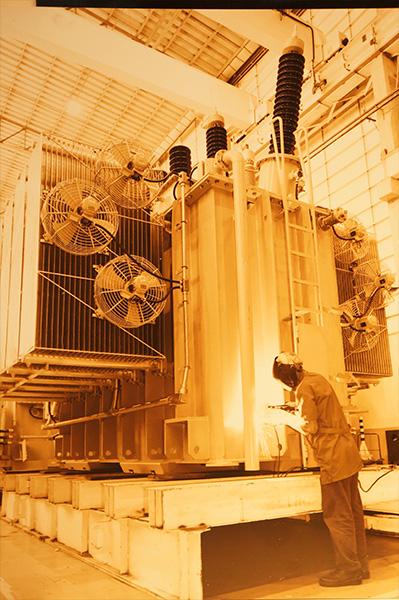

Transformers

The role of transformers is not as widely known by people in general as that of electric motors and generators. Do you know what a transformer transforms?

Invented by Faraday in 1831, the transformer is a device installed between two circuits. It has input and output terminals. Upon receiving a certain voltage at the input terminals, it establishes through electromagnetic induction, a different voltage at the output terminals. Thus, the currents will also be different in each circuit. Therefore, a transformer transforms voltage and electric currents.